Brands

- 80/20

- Atos Hydraulics

- Aventics

- Belden

- Bucher Hydraulics

- Coval

- Denso Robotics

- DieQua Corporation

- Doosan Robotics

- Dorner Conveyors

- Fortress

- Gems Sensors

- Hawe Hydraulics

- Hirschmann

- IAI

- Kollmorgen

- Laurel Electronics

- Lumberg Automation

- Macron Dynamics

- Madison

- Micromatic

- Miller Fluid Power

- Murrelektronik

- NSK

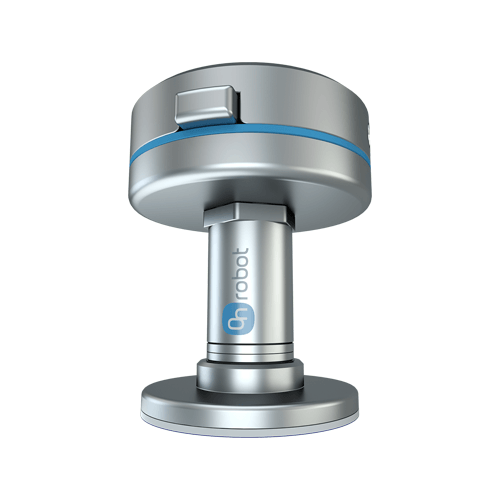

- OnRobot

- Patlite

- Pro-face

- PULS

- Schmersal

- Schunk

- Secomea

- Sick

- Swivellink

- Thomson

- Tolomatic

- Turck

- Versa Valves

- Weidmüller

- Weintek

- West Control Solutions

- Wilkerson

- Yaskawa Drives

- Yaskawa Motion

- Yaskawa Motoman

Shop by Category

Available from Neff Power in Missouri, Illinois, Kansas, Arkansas, Oklahoma, Texas, Arizona and New Mexico.

OnRobot offers a full range of state-of-the-art robotic arm grippers, sensors and tool changers for industrial automation. All of OnRobot's products work with any collaborative or light industrial robot arm.

Grippers, force/torque sensors and tool changers are game changers within collaborative automation, opening up new automation and optimization possibilities never seen before.

Each of the OnRobot products comes with a built-in electronic quick changer that helps make programming and installation simple and easy. OnRobot solutions are instantly deployable, so you can get your production up and running in no time, allowing your investment to earn itself back from day one.

OnRobot is compatible with all brands and varieties industrial and collaborative robots.

Regardless of which process you want to improve, and which robot you prefer, the One System Solution helps you automate swiftly and seamlessly.

Products & Solutions from OnRobot

RG2 Gripper

.jpg)

RG6 Gripper

RG2-FT Gripper

Gecko Single Pad Gripper

3FG15 Three Finger Gripper

Soft Gripper

VG10 Electric Vacuum Gripper

VGC10

OnRobot Eyes

OnRobot Screwdriver

OnRobot Sander

Hex 6-Axis Force/Torque Sensor

Quick Changer

Dual Quick Changer

Accessories

Benefits of using OnRobot gripping systems

- RG2 - a flexible finger for lighter jobs, picking and placing items up to 2kg

- RG6 - flexible, with a larger reach and a little more muscle, payload of 6kg

- RG2-FT - for high-precision assembly applications where fingertip sensitivity is required

- VG10 Electrical Vacuum Gripper - for larger objects or applications where two parts should be moved separately, payload up to 10kg

- VGP20 Electrical Vacuum Gripper - no compressed air required - 20kg (44.1LB) payload - industry's most powerful electric vacuum gripper

- HEX Sensor - Precision insertion tasks, handles variation like a pro, surface finishing and gluing

- Built-in proximity sensors to detect whether a part is present

- Unique technology for flat and smooth objects

- Objects with holes, like PCB, can be handled easily

- Faster setup, less running costs, less noise

- Plastic

- Metal

- Cardboard

- Glossy packaging

- Wood

- Glass

- Machine tending

- Assembly

- Pick & place

- Packaging & palletizing

- Quality testing and inspection

- Surface finishing

Visit www.onrobot.com for more information.

REady to learn how onrobot Grippers can improve your automated process?

Tell us about your application, and a Neff Power engineer will be in touch soon.