Shop by Category

Available from Neff Power in Missouri, Illinois, Kansas, Arkansas, Texas, Oklahoma, Arizona & New Mexico.

Why choose IAI SCARA Robots?

- From an abundant lineup of 92 total models, you can find one that is most suitable for your needs

- Affordable, highly precise and rigid actuators have 1/5th the running cost of a pneumatic system

- Next-generation electric actuators are the solution for space-constrained applications

- Actuators offer protection conforming to IP54~IP67 and are a desirable solution when operated in adverse environments

- High-speed cartesian robot that shortens assembly/inspection cycle times by operating at high speed, ensuring high rigidity, and demonstrating excellent straight-moving performance

Why choose IAI Cartesian Robots?

- Both Single Axis and Multi-Axis varieties available, with up to 6-axis configurations.

- Reduce space and cycle time with multi-slider types.

- Increase capability with rotational axis types.

- Any model can be customized to meet your specific needs.

What is IAI's new ELECYLINDER?

- This new simple electric linear actuator series can be operated only by ON/OFF signal like solenoid valve.

- It's easy to operate for beginners of electric actuators.

- You can adjust AVD (A=Acceleration, V=Velocity, D=Deceleration) individually by input percentage.

- It can start/stop at high speed smoothly.

- Cycle-time and trouble recovery time will be reduced.

ELECYLINDER Application #1: Improving Inspection of Shampoo Bottles

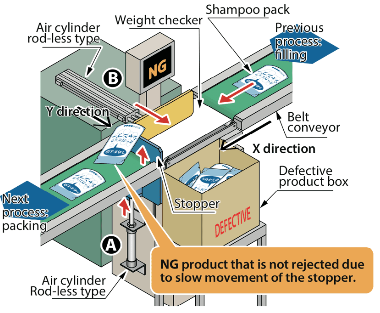

Before Improvement

Problem: defective products got past the rejection process due to the slow movement of the air cylinder (A) that was caused by the fluctuation of the source of air pressure. When the movement is too slow, an alarm activates and a temporary stop occurs.

Likewise, before the air cylinder (B) discharges a defect, a new shampoo pack feeds onto the weight checker conveyor, which disables a weight measurement. When that fails, the alarm activates and a temporary stop occurs.

3 times x 10 minutes = 30 minutes per day of recovery time.

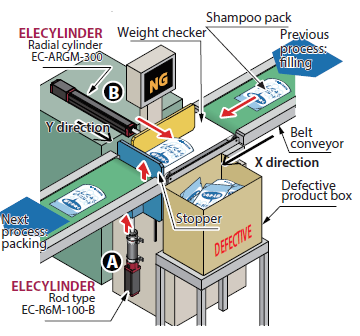

After Improvement

Solution: Replace air cylinders with ELECYLINDERs from IAI.

Thanks to no speed fluctuations, defective products are not getting past the rejection process. The alarm no longer activates, and processes function as normal.

Because there are no speed fluctuations, another shampoo pack is no longer fed onto the weight checker conveyor before the proper time. The alarm does not activate, and processes continue as normal.

Zero time lost during recovery per day!

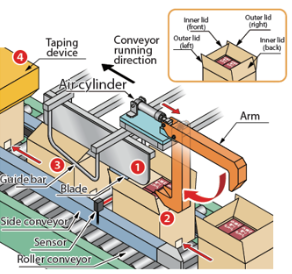

ELECYLINDER Application #2: Improving Packing of Cardboard Boxes

Before Improvement

Problem: sometimes the back inner lids could not be folded because of delayed timing of the air cylinder. When a problem occurs in folding the inner lids, the conveyor stops to adjust the speed controller of the air cylinder and to redo the packing. This adjustment cycle is 10 minutes long, and occurs 3 times per day.

Cardboard boxes are transferred on a conveyor and a front lid is folded inward by blade. After a sensor detects the cardboard box, the air cylinder moves down the arm to fold the back inner lid inward. Errors at this point in the cycle result in recovery time.

3 times x 10 minutes = 30 minutes per day of recovery time.

After Improvement

Solution: Replace air cylinder with ELECYLINDER from IAI.

There is no delayed timing of the arm's downward movement, which eliminates the folding errors of the back inner lid. Speed controller adjustment and re-packing of 30 minutes per day have been eliminated.

After successful folding of the inner lids, the the cardboard box continues the folding process. The cardboard box moves forward with outer lids touching the guide bars, the outer lids are gradually folded inwards. A successfully folded box is then transferred to the taping device.

Zero time lost during recovery per day!

Visit www.intelligentactuator.com for more information

Ready to discover how your process can benefit from IAI solutions?

Tell us about your application, and a Neff Power engineer will be in touch soon.