Shop by Category

Available from Neff Power in Missouri, Illinois, Kansas, Arkansas, Oklahoma, Arizona, New Mexico, and Texas.

4-Axis SCARA Robots

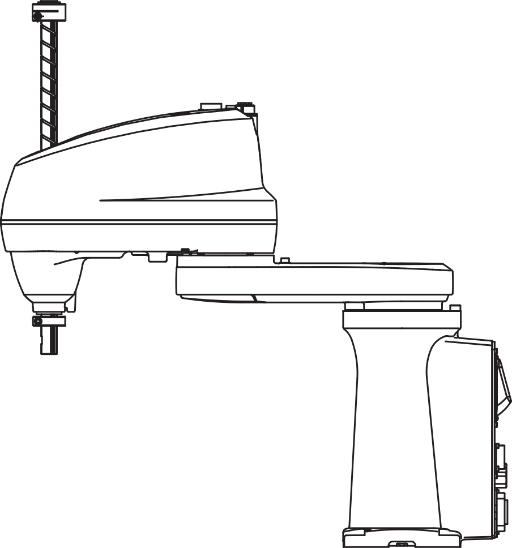

HS-A1 Series

The HS-A1 Series compact, four-axis SCARA robots offer the highest speed and repeatability in their class. Although these small industrial robots have a compact, space-saving design, they have a large load-handling capability, with a maximum payload of 5 kg. In addition, their large, 0.1 kgm2 maximum allowable moment of inertia enables a wide range of end effectors and applications. All HS-A1 Series robots are available in dust- and mistproof (IP65) or ISO 4 (class 10) cleanroom configurations. ANSI and CE compliance allows global deployment. UL-listed models are available for both the U.S. and Canada.

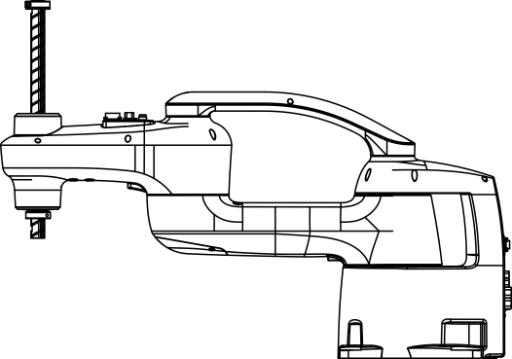

HSR Series

The HSR Series uses advanced vibration control, a newly designed, highly rigid lightweight arm and improved heat dissipation in the base unit to achieve new levels of continuous high-speed performance and repeatability.

- Quick acceleration

- Runs continuously at high speed

- Stops precisely

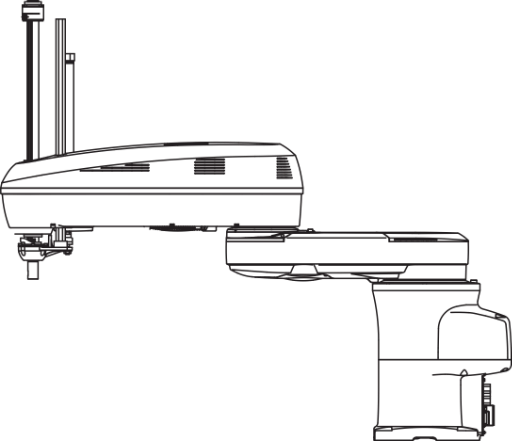

HM Series

The HM Series four-axis SCARA robots offer outstanding speed and repeatability. Although these small industrial robots have a compact, space saving design, they can handle 20 kg payloads. In addition, their maximum allowable moment of inertia of 0.45 kgm2 is six times larger than that of conventional robots, permitting a wide variety of applications. All HM Series robots are available in standard or dust- and mistproof (IP65) configurations. ANSI and CE compliance allows global deployment. UL listed models are available for both the U.S. and Canada.

Benefits of Denso Robotics 4-Axis SCARA Robots

- Designed to run trouble-free with only minimal scheduled maintenance, which results significant savings in maintenance costs and the cost of production downtime due to overly frequent or lengthy maintenance procedures

- Compact robot design saves valuable factory floor space and reduces integration time and costs.; internally routed electrical wires and air lines prevent interference with other equipment

- Controllers come preconfigured, substantially cutting down on setup and development time

- Lightweight robot arms and energy-efficient motors result in lower energy consumption and therefore lower operating costs

- Use of harmonic-drive motors allows its robots to maintain their high speeds in continuous two- and three-shift duty, year and year, essential to maximizing productivity

- Offers support and upgrades for up to 10 years after robot model has been discontinued.

More Products & Solutions from Denso Robotics

- 5- and 6-Axis Robots

- 7th Axis Robot Controls

- SCARA Robots

- Safety Robot Controls

- Integrated Compact Robots

- Controllers

- Software

- Accessories

Why choose Denso Robotics solutions?

Low Maintenance

DENSO robots are designed to run trouble-free with only minimal scheduled maintenance. This results in significant savings in maintenance costs as well as the cost of production downtime due to overly frequent or lengthy maintenance procedures.

Ease of Integration

DENSO’s compact robot design saves valuable factory floor space and reduces integration time and costs. Internally routed electrical wires and air lines prevent interference with other equipment, eliminating the cost of replacement due to unnecessary wear and tear.

Ease of Setup, Programming, and Networking

DENSO robot controllers come preconfigured, substantially cutting down on setup and development time. Programming is made quick and easy by DENSO’s offline programming software, which includes 3D simulation as standard. And networking is only a matter of entering an IP address.

Low Energy Consumption

DENSO’s lightweight robot arms and energy-efficient motors result in lower energy consumption and therefore lower operating costs.

High Reliability

DENSO’s use of harmonic-drive motors allows its robots to maintain their high speeds in continuous two- and three-shift duty, year after year, essential to maximizing productivity. In addition, the motors’ high maximum moment of inertia means the robots can handle higher payloads with less strain, reducing wear and thus minimizing the risk of downtime due to repair.

Long Working Life

Many robot manufacturers introduce new models every few years and quickly stop supporting older models, which then become obsolete and need to be replaced. In contrast, DENSO offers support and upgrades for up to 10 years after a robot model has been discontinued. This eliminates the need for unnecessarily premature equipment replacement, greatly reducing capital investment costs.

REady to discover how your process can benefit from Denso Robotics?

Tell us about your application, and a Neff Power engineer will be in touch soon.